Finding reliable wholesale phone screen suppliers can be challenging. Many repair shop owners struggle with inconsistent quality, long delivery times, and suppliers who don’t understand business needs.

The best wholesale phone screen suppliers offer multiple quality grades from INCELL and OLED to OEM and original refurbished options. Look for suppliers with 5+ years of industry experience, consistent quality control processes, and competitive pricing that balances cost and reliability.

After 11 years in the phone parts industry, I’ve seen countless repair businesses struggle to find the right balance between price and quality. Let me share what I’ve learned about sourcing wholesale phone screens that will keep both your profit margins and customers happy.

How to Choose Wholesale Phone Screen Replacements for Maximum Profit?

Price isn’t everything when sourcing screens. I’ve watched repair shops lose customers after installing cheap screens that failed within weeks, damaging their reputation permanently.

Quality wholesale screen replacements should offer 3–6 quality grades depending on budget and customer needs. Premium options include Original New and Original Refurbished1 with 90%+ color accuracy, while mid-range OLED and INCELL screens provide good value with 80–90% color reproduction.

When selecting wholesale phone screen replacements, you need to consider several critical factors beyond just the initial price. I recommend creating a comprehensive supplier evaluation system based on what I’ve learned working with repair shops across different markets.

First, understand the technology differences. LCD screens use a backlight and are typically less expensive but offer lower contrast ratios. OLED screens provide better color accuracy and contrast but at a higher price point. For iPhone repairs, deciding between INCELL, OLED, and Original screens will significantly impact your business model.

Here’s a breakdown of quality tiers I recommend stocking:

| Quality Grade | Best For | Avg. Wholesale Price | Expected Markup |

|---|---|---|---|

| Original New | Premium clients | $85–120+ | 70–100% |

| Original Refurbished | High-end repairs | $65–90 | 60–90% |

| OLED/SOFT OLED | Mid-range market | $45–70 | 50–80% |

| INCELL (HD/FHD) | Budget-conscious | $25–45 | 40–70% |

Remember that maintaining a diverse inventory allows you to serve different customer segments. I’ve found that repair shops that offer multiple price points typically achieve 35% higher customer retention rates than those offering only one quality option.

What Determines Wholesale Phone Screen Prices in 2025?

I’ve seen many repair shop owners shocked by the wide range of prices for seemingly identical screens. One customer once told me he paid three different prices for the "same" iPhone 12 screen from three suppliers.

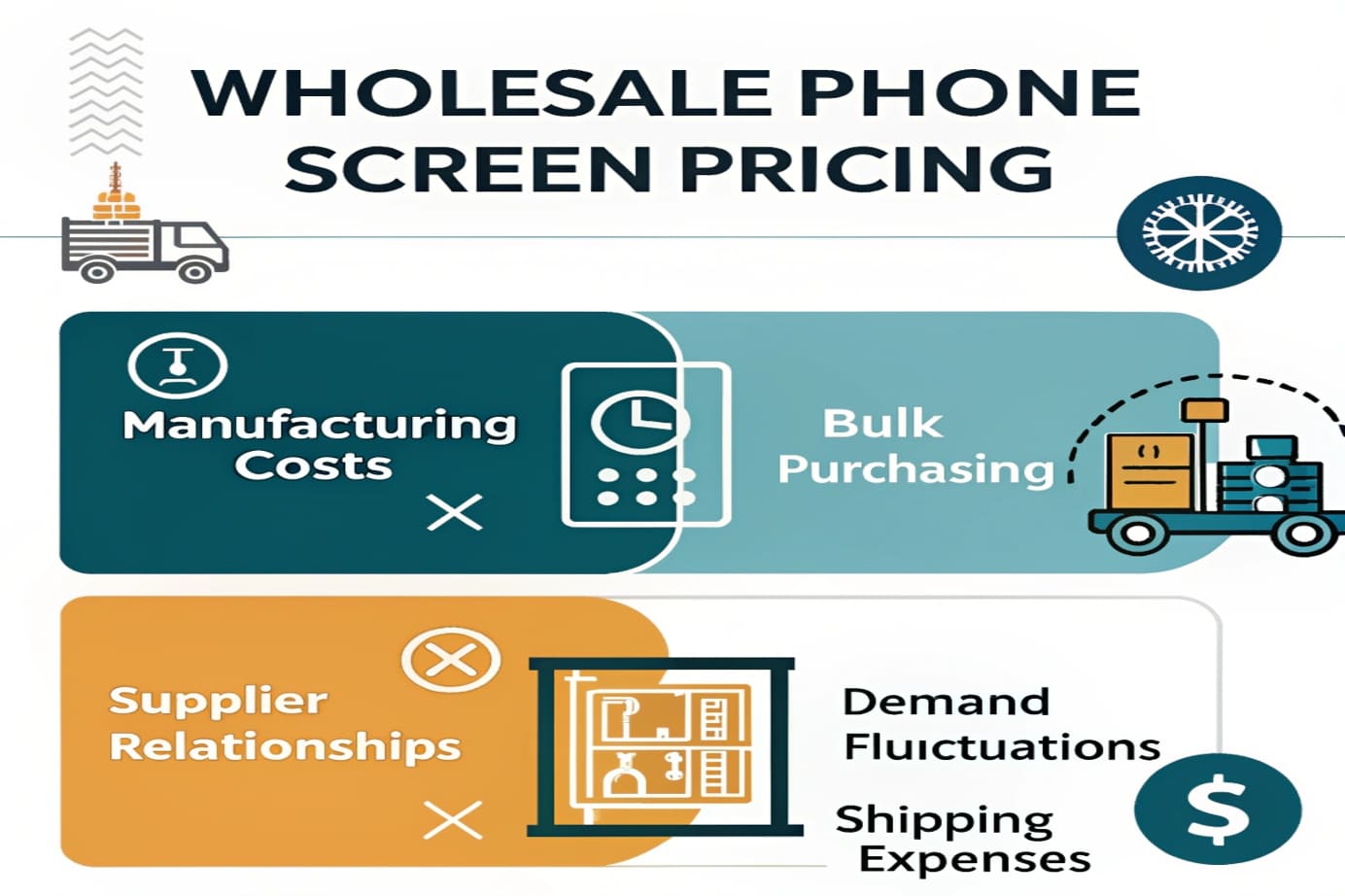

Wholesale phone screen prices vary based on quality grade, with original displays ($85-120) costing significantly more than INCELL alternatives ($25-45). Market demand for newer models drives prices higher, while order volume and supplier relationships can reduce costs by 10-25%.

Understanding price determinants helps you make informed purchasing decisions and explain costs to customers. After working with hundreds of repair businesses, I’ve identified several key factors affecting wholesale screen prices beyond just quality grades.

Supply chain position significantly impacts pricing. Buying directly from manufacturers or primary distributors typically saves 15-30% compared to secondary wholesalers. However, minimum order quantities (MOQs) often make this prohibitive for smaller operations. This creates an opportunity for strategic partnerships where multiple repair shops combine orders to access better pricing.

Market timing also matters considerably. New model releases typically follow a predictable price curve. I’ve observed that screen prices for flagship models drop approximately:

- 5-10% at 3 months after release

- 15-25% at 6 months after release

- 30-40% at 12 months after release

Savvy buyers plan inventory purchases around these cycles. Additionally, understanding regional pricing differences allows global purchasers to identify arbitrage opportunities.

| Phone Model | US Wholesale Avg | EU Wholesale Avg | Asian Wholesale Avg |

|---|---|---|---|

| iPhone 15 Pro | $95-115 | $105-125 | $85-105 |

| Samsung S24 | $85-105 | $90-110 | $75-95 |

| iPhone 14 | $65-85 | $70-90 | $55-75 |

| Xiaomi 13 | $55-70 | $60-75 | $45-65 |

Building long-term supplier relationships remains one of the most effective ways to secure favorable pricing, as I’ve consistently seen established buyers receive 10-15% better pricing than new customers on identical products.

Where to Source Quality Phone LCD Parts at Competitive Prices?

After ordering screens from various suppliers, I discovered many weren’t properly testing their LCD parts. Customers were returning phones with issues like ghost touch and dead pixels within days.

Quality phone LCD parts1 come from specialized wholesalers with direct factory relationships and robust testing procedures. Look for suppliers offering 100% functional testing, 30+ day warranties, and transparent quality grading systems to ensure parts meet repair industry standards.

Finding reliable sources for phone LCD parts requires understanding the complex supply chain behind these components. After more than a decade in this industry, I’ve mapped out how the most successful repair businesses consistently source quality LCD parts without overpaying.

The supplier’s testing protocol is perhaps the most crucial factor. Professional wholesalers should implement multi-stage testing including:

- Initial electrical testing (100% of units)

- Brightness and color calibration verification

- Touch sensitivity analysis across the entire screen surface

- Stress testing to identify potential early failures

I recommend requesting detailed information about testing procedures and rejection rates. Quality suppliers typically have a 5-10% rejection rate during quality control processes, so be wary of suppliers claiming perfect pass rates as this often indicates inadequate testing.

Packaging methods also significantly impact LCD part quality. Proper packaging should include:

| Packaging Element | Purpose | Impact on Quality |

|---|---|---|

| Anti-static bags | Prevents electrical damage | Reduces DOA rate by ~8% |

| Corner protectors | Prevents frame bending | Maintains touch accuracy |

| Individual boxing | Prevents pressure damage | Preserves display uniformity |

| Humidity control | Prevents condensation | Extends component lifespan |

Beyond individual part quality, supplier stability2 matters tremendously for repair businesses. I’ve seen numerous repair shops struggle when their parts supplier suddenly changed quality standards or went out of business. Look for wholesalers with 5+ years in business, transparent company information, and consistent communication practices.

Conclusion

Finding reliable wholesale phone screen suppliers requires balancing quality, price, and service. By understanding quality grades, price factors, and proper testing procedures, you’ll secure parts that satisfy customers and protect your business reputation.