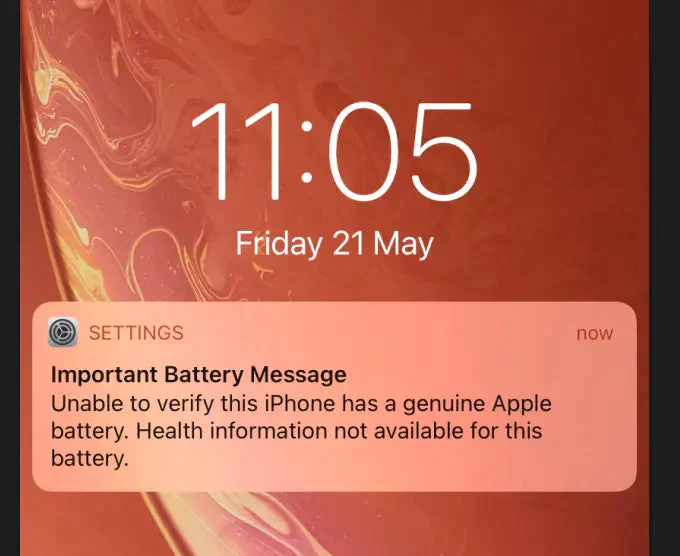

Screen replacement shops frequently encounter Apple’s irritating "Unknown Part" warnings after installing new displays. These warnings confuse customers and damage business reputation, creating frustrating situations for repair technicians with otherwise perfectly functioning replacements.

IC transfer (also called IC swap or IC replant) is the process of moving the original display’s control chip to a replacement screen, preserving critical functions like True Tone and avoiding "unknown part" warnings. This technique maintains full functionality while allowing more affordable screen replacement options.

Over my 11 years in the mobile parts industry, I’ve watched screen replacement evolve dramatically. What once required simple mechanical skills now demands microsoldering expertise as Apple increasingly restricts third-party repairs. IC transfer has become the gold standard for quality-focused repair shops who want to provide an authentic repair experience without the Apple price tag. Let me share what I’ve learned about this critical technique.

What is IC Swap?

A repair shop owner recently told me how a customer returned angrily after another shop’s screen replacement disabled True Tone and showed persistent warnings. The customer thought their phone was permanently damaged until our shop fixed it with proper IC transfer.

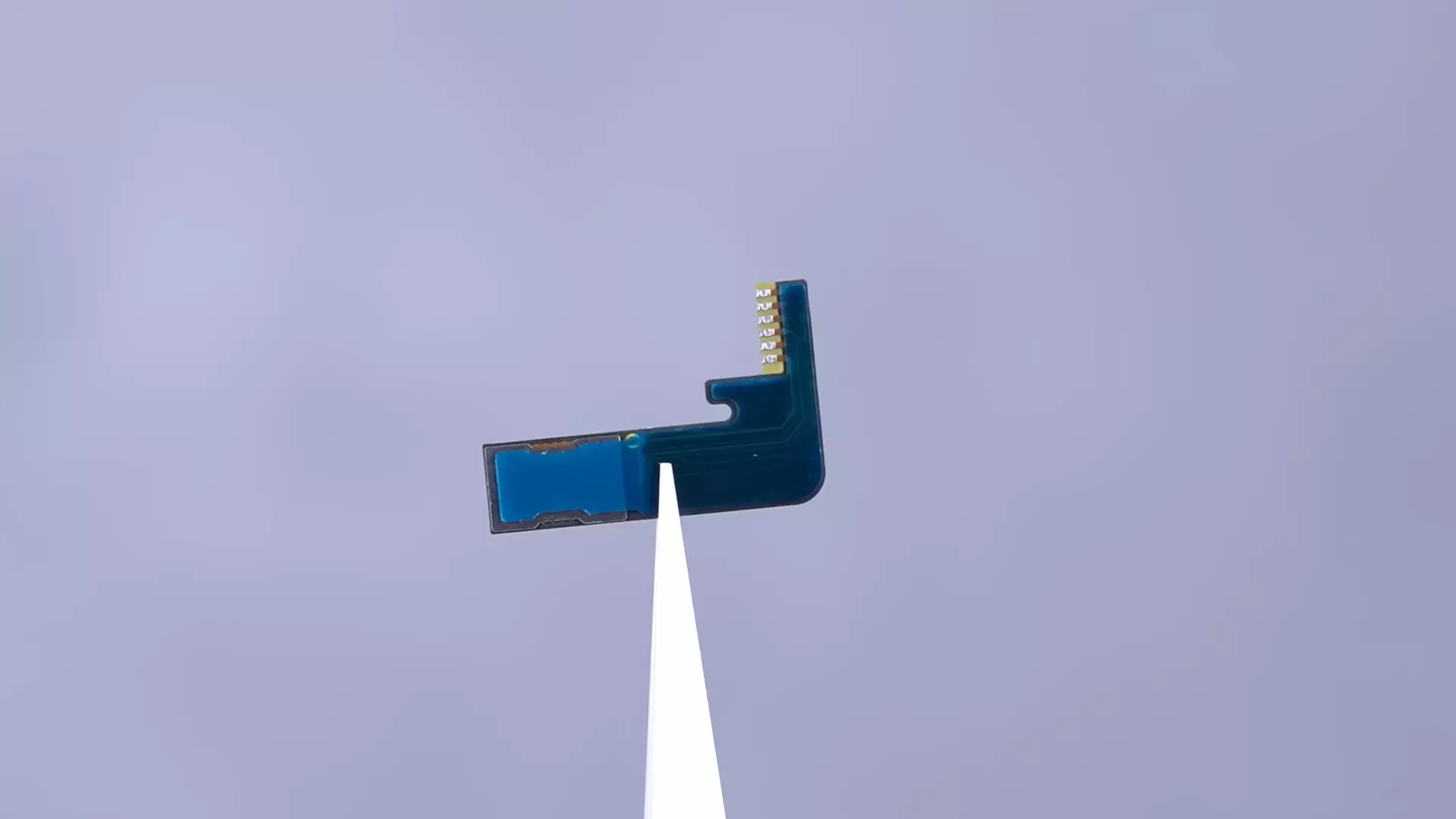

IC swap is a technical procedure where a skilled technician transfers the small control chip (integrated circuit) from the original iPhone screen to a replacement display. This chip contains device-specific information that enables full functionality, including True Tone color calibration and eliminates "non-genuine display" warnings.

The IC transfer process has become an essential skill in professional iPhone repair, particularly as Apple has implemented increasingly sophisticated part-pairing systems in their devices. Understanding what exactly this procedure involves requires looking at both the hardware and software elements that make it necessary.

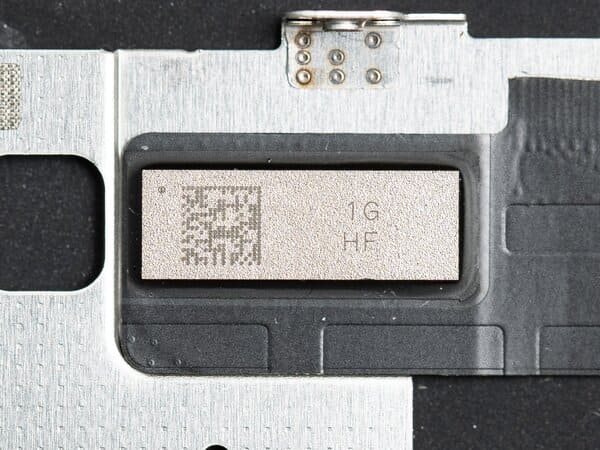

At its core, the IC (Integrated Circuit) in an iPhone display serves several critical functions beyond simply driving the pixels. This tiny chip, typically just a few millimeters square, contains:

- Device-specific calibration data – Each display is calibrated at the factory for precise color accuracy

- Authentication information – Cryptographic data that allows iOS to verify the display as Apple-approved

- Serial number records – Unique identifiers that associate the component with a specific device

- True Tone calibration – Specialized data for the ambient light color adjustment feature

When a screen is damaged and needs replacement, simply installing a new screen assembly (even a high-quality one) will result in the loss of these functions because the new screen has either a blank IC or one programmed for a different device.

IC swap addresses this by physically transferring the original chip to the new display assembly. This preserves all device-specific data and functionality while allowing the use of more affordable replacement parts.

For repair shops, this technique has become increasingly important with each iPhone generation. Starting with the iPhone 8 and X, Apple began implementing more restrictions, and by the iPhone 11 series, replacing a screen without transferring or programming the IC results in persistent warning messages and disabled features that significantly impact the user experience.

The alternative to IC transfer is using Apple’s official repair program, which costs substantially more or using specialized programmers that attempt to write new data to replacement screens. However, programming solutions often have limitations and may stop working after iOS updates, making physical IC transfer the most reliable approach for repair businesses focused on long-term customer satisfaction.

Why IC Swap?

Last month, a repair business owner called me in frustration after spending thousands on "plug-and-play" screens that suddenly triggered warnings after an iOS update. He switched to IC transfer and hasn’t had a single customer complaint since.

IC swap preserves critical iPhone display functions including True Tone color adjustment, ambient light sensing, and automatic brightness. It eliminates persistent "non-genuine display" warnings that annoy customers and prevents potential feature limitations imposed by Apple’s iOS updates on third-party screens.

The decision to implement IC swap as part of a repair business’s standard procedures is driven by several compelling technical and business reasons. Understanding these factors helps repair shop owners make informed decisions about their service offerings and parts purchasing.

The primary technical advantages of performing IC transfers include:

-

True Tone Preservation: The True Tone feature adjusts display color temperature based on ambient lighting conditions, creating a more natural viewing experience. This feature requires specific calibration data stored on the original display’s IC. Without transfer, this feature becomes permanently disabled, resulting in a noticeable difference in display quality.

-

Warning Message Elimination: Since iOS 13, Apple has implemented increasingly aggressive notification systems for non-genuine parts. These warnings appear during startup, in Settings, and as persistent notifications. They create customer concerns about repair quality, even when the replacement screen functions perfectly otherwise.

-

Future-Proofing Against Restrictions: Apple has a history of implementing additional restrictions with iOS updates. IC transfer ensures the device recognizes the display as genuine, protecting against potential future limitations that might be imposed on third-party components.

-

Full Feature Compatibility: Beyond True Tone, other features like auto-brightness calibration, ambient light sensing accuracy, and even touch sensitivity can be affected by non-genuine displays without proper IC transfer.

From a business perspective, IC transfer offers significant advantages:

| Benefit | Without IC Transfer | With IC Transfer |

|---|---|---|

| Customer Satisfaction | Lower due to warnings and missing features | Higher with full functionality |

| Warranty Returns | 15-25% higher return rate | Significantly reduced returns |

| Pricing Model | Lower margins due to commodity perception | Premium service commanding higher prices |

| Competitive Advantage | Difficult to differentiate from budget repair options | Clear quality difference visible to customers |

For repair business owners, implementing IC transfer represents an investment in quality and customer satisfaction. While it requires additional equipment, training, and slightly longer repair times, the benefits typically outweigh these costs through higher customer satisfaction, fewer returns, and the ability to position their business as a premium service provider.

As one repair shop owner told me: "IC transfer changed our business model completely. We now charge $20 more for screen replacements than our competitors, but our customers happily pay it because they know they’re getting a repair that’s functionally identical to Apple’s service, just without the Apple price tag."

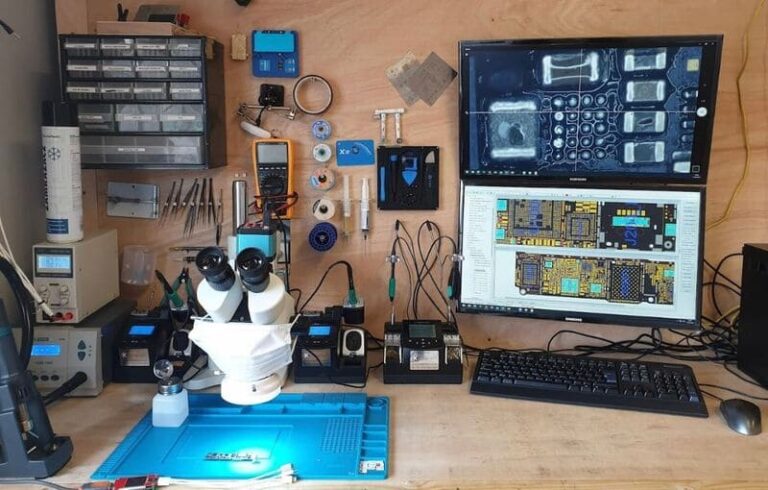

Tools and Equipment

When I first started teaching IC transfer workshops, I noticed shops investing in cheap equipment often abandoned the practice due to frustration and failures. Quality tools make all the difference between consistency and constant headaches.

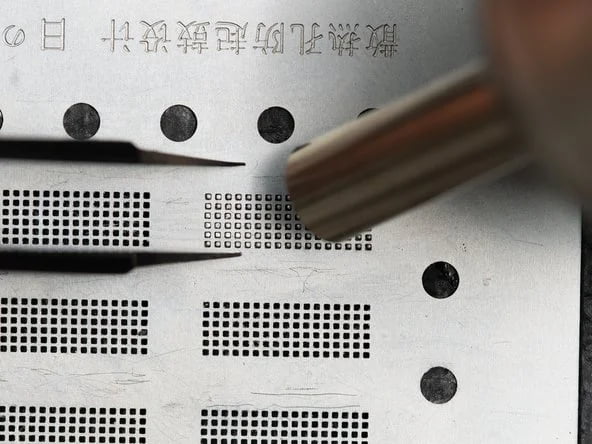

Successful IC swap requires: a quality hot air rework station (temperature-controlled, 100-600°C), precision tweezers, magnification system (microscope or loupe), flux, high-quality solder paste, kapton tape, PCB holder/fixture, cleaning supplies, and a clean, well-lit workspace. Professional setups typically cost $500-1500 depending on equipment quality.

Selecting the right equipment for IC transfer operations is crucial for repair businesses. The quality and capabilities of your tools directly impact success rates, repair times, and technician satisfaction. Based on our experience supporting thousands of repair businesses, here’s a comprehensive breakdown of the essential tools and equipment:

-

Hot Air Rework Station – This is the core tool for IC transfer operations and the one area where investment quality matters most.

Key specifications to consider:

- Temperature range: 100-600°C minimum

- Temperature stability: ±5°C or better

- Airflow control: Multiple levels with fine adjustment

- Nozzle options: Various sizes including specialized IC nozzles

- Display type: Digital with precise temperature indication

Recommended brands include Hakko, Quick, Atten, and JBC for professional use. While entry-level stations start around $100, professional models in the $300-700 range offer significantly better temperature stability and control, which directly translates to higher success rates and less component damage.

-

Magnification System – Proper visualization is essential for precise chip alignment and inspection.

Options include:

- Stereo microscopes: 10-45x magnification, $200-600

- Digital microscopes: 10-200x magnification with screen display, $100-400

- Magnifying lamps with LED lighting: 3-5x magnification, $50-150

For beginners, a good digital microscope offers the best balance of affordability and functionality. Advanced technicians often prefer stereo microscopes for their depth perception advantages during component placement.

-

Precision Tools

These tools handle the delicate components during the transfer process:

| Tool | Purpose | Quality Considerations |

|---|---|---|

| ESD-safe tweezers | IC handling and placement | Anti-magnetic, fine tips, comfortable grip |

| PCB holders/fixtures | Securing boards during work | Stability, adjustability, heat resistance |

| Cleaning brushes | Flux removal and pad cleaning | Soft bristles, chemical resistance |

| Kapton tape | Protecting surrounding components | Heat resistance, clean removal |

-

Consumables – These materials are used during the process and need regular replacement:

- Flux: No-clean RMA flux is recommended for most IC transfers

- Solder paste: Lead-based with lower melting point (183°C) is easier for beginners

- Isopropyl alcohol (99%): For cleaning boards before and after work

- Desoldering wick: For removing excess solder and cleaning pads

- Cotton swabs and lint-free wipes: For precision cleaning

-

Auxiliary Equipment – These items improve workflow efficiency and success rates:

- Preheating platform: Reduces thermal shock during hot air application

- Fume extraction system: Removes potentially harmful flux fumes

- Board cleaning station: For thorough flux removal after soldering

- Test fixtures: For verifying display functionality after transfer

For repair businesses just starting with IC transfer, a budget of approximately $800-1,000 will cover essential equipment at acceptable quality levels. Established businesses looking to optimize their IC transfer operations should consider investing $1,500-2,500 in professional-grade equipment that offers better precision, reliability, and longevity.

Beyond the initial equipment investment, ongoing training and practice are equally important. We recommend new technicians practice on 5-10 non-functional boards before attempting customer repairs. Many suppliers, including FIZON, offer practice kits specifically designed for IC transfer training.

Tools and Equipment

When I first started teaching IC transfer workshops, I noticed shops investing in cheap equipment often abandoned the practice due to frustration and failures. Quality tools make all the difference between consistency and constant headaches.

Successful IC swap requires: a quality hot air rework station (temperature-controlled, 100-600°C), precision tweezers, magnification system (microscope or loupe), flux, high-quality solder paste, kapton tape, PCB holder/fixture, cleaning supplies, and a clean, well-lit workspace. Professional setups typically cost $500-1500 depending on equipment quality.

Selecting the right equipment for IC transfer operations is crucial for repair businesses. The quality and capabilities of your tools directly impact success rates, repair times, and technician satisfaction. Based on our experience supporting thousands of repair businesses, here’s a comprehensive breakdown of the essential tools and equipment:

-

Hot Air Rework Station – This is the core tool for IC transfer operations and the one area where investment quality matters most.

Key specifications to consider:

- Temperature range: 100-600°C minimum

- Temperature stability: ±5°C or better

- Airflow control: Multiple levels with fine adjustment

- Nozzle options: Various sizes including specialized IC nozzles

- Display type: Digital with precise temperature indication

Recommended brands include Hakko, Quick, Atten, and JBC for professional use. While entry-level stations start around $100, professional models in the $300-700 range offer significantly better temperature stability and control, which directly translates to higher success rates and less component damage.

-

Magnification System – Proper visualization is essential for precise chip alignment and inspection.

Options include:

- Stereo microscopes: 10-45x magnification, $200-600

- Digital microscopes: 10-200x magnification with screen display, $100-400

- Magnifying lamps with LED lighting: 3-5x magnification, $50-150

For beginners, a good digital microscope offers the best balance of affordability and functionality. Advanced technicians often prefer stereo microscopes for their depth perception advantages during component placement.

-

Precision Tools – These handle the delicate components during the transfer process: Tool Purpose Quality Considerations ESD-safe tweezers IC handling and placement Anti-magnetic, fine tips, comfortable grip PCB holders/fixtures Securing boards during work Stability, adjustability, heat resistance Cleaning brushes Flux removal and pad cleaning Soft bristles, chemical resistance Kapton tape Protecting surrounding components Heat resistance, clean removal -

Consumables – These materials are used during the process and need regular replacement:

- Flux: No-clean RMA flux is recommended for most IC transfers

- Solder paste: Lead-based with lower melting point (183°C) is easier for beginners

- Isopropyl alcohol (99%): For cleaning boards before and after work

- Desoldering wick: For removing excess solder and cleaning pads

- Cotton swabs and lint-free wipes: For precision cleaning

-

Auxiliary Equipment – These items improve workflow efficiency and success rates:

- Preheating platform: Reduces thermal shock during hot air application

- Fume extraction system: Removes potentially harmful flux fumes

- Board cleaning station: For thorough flux removal after soldering

- Test fixtures: For verifying display functionality after transfer

For repair businesses just starting with IC transfer, a budget of approximately $800-1,000 will cover essential equipment at acceptable quality levels. Established businesses looking to optimize their IC transfer operations should consider investing $1,500-2,500 in professional-grade equipment that offers better precision, reliability, and longevity.

Beyond the initial equipment investment, ongoing training and practice are equally important. We recommend new technicians practice on 5-10 non-functional boards before attempting customer repairs. Many suppliers offer practice kits specifically designed for IC transfer training.

Important Considerations

During a recent supplier conference, several repair shop owners shared horror stories about damaged motherboards and wasted screens from rushed IC transfers. Taking time to master this technique prevents expensive mistakes.

Successful IC transfer requires proper training, practice on non-customer devices, and understanding the risks of component damage. Temperature control is critical—too hot damages components, too cool creates weak connections. Always verify the donor IC is functional before transfer, and maintain anti-static precautions throughout the process.

IC transfer, while highly beneficial, comes with significant technical challenges and considerations that repair businesses should be aware of before implementing this service. Understanding these factors helps prevent costly mistakes and ensures consistent quality in screen replacement services.

-

Risk of Component Damage

The IC transfer process exposes sensitive electronic components to high temperatures and physical manipulation. Common risks include:

- Pad lifting: Excessive heat or force can separate copper pads from the PCB

- IC damage: Overheating can internally damage the chip, rendering it useless

- Broken traces: Microscopic circuit pathways can break during the process

- Damaged flex connectors: Heat can affect nearby flexible circuit connections

Mitigation strategy: Begin with proper training, use temperature-controlled equipment, and practice gradual heating and cooling techniques. Always work on non-customer devices until proficiency is achieved.

-

Donor IC Functionality Verification

Not all original ICs are suitable for transfer. If the original display failed due to IC issues rather than physical damage, transferring that IC will simply transfer the problem. Before investing time in IC transfer:

- Test the original display’s functionality if possible

- Inspect the IC visually for physical damage or corrosion

- Consider the failure mode of the original screen (impact damage vs. electronic failure)

- Have a contingency plan if the transfer doesn’t resolve all issues

-

Display Quality Considerations

IC transfer preserves functionality but doesn’t affect the fundamental quality of the replacement display. Key factors include:

Display Aspect Considerations LCD/OLED quality Color accuracy, brightness, contrast Touch sensitivity Response accuracy, multi-touch capabilities Glass quality Hardness, oleophobic coating, clarity Assembly precision Alignment, dust/debris under glass The best results come from combining IC transfer with high-quality replacement screens. Using premium displays with transferred ICs provides both full functionality and excellent visual quality.

-

Business Model Integration

Adding IC transfer to your repair services requires careful business planning:

- Pricing strategy: IC transfer typically adds $20-40 to the service cost

- Repair time: Allow 15-30 additional minutes per repair

- Customer education: Explain the benefits to justify the higher price

- Warranty considerations: Transferred ICs generally perform reliably but may have slightly higher failure rates than untouched components

-

Alternative Solutions Comparison

IC transfer is not the only solution for maintaining full functionality in screen replacements. Alternatives include:

- Programmers: Devices that write new data to replacement screen ICs

- Apple Authorized Repair: Using official parts with pre-programmed ICs

- Copy IC solutions: Some suppliers offer screens with pre-copied ICs

Each alternative has trade-offs in terms of cost, reliability, and future-proofing. IC transfer typically offers the best balance of these factors for independent repair businesses, though it requires more technical skill and time investment.

-

iOS Update Considerations

Apple frequently changes how iOS interacts with display components through software updates. This can affect:

- Authentication methods for display verification

- Warning message implementations

- Feature restrictions on non-genuine parts

IC transfer has proven to be the most resilient solution through multiple iOS versions, making it a safer long-term investment than programming solutions that may become obsolete after updates.

-

Supplier Selection for Replacement Screens

Not all replacement screens are equally suitable for IC transfer. Key considerations include:

- PCB design compatibility with original ICs

- Pad quality and layout precision

- Pre-applied adhesive quality

- Availability of practice/training components

At FIZON, we specifically design our premium replacement screens with IC transfer compatibility in mind, ensuring proper pad spacing, high-quality PCB materials, and consistent layouts that match original specifications.

For repair businesses considering implementing IC transfer services, I recommend a gradual approach: first, invest in proper equipment and training; second, practice extensively on non-customer devices; third, introduce the service at a premium price point that reflects its added value. Done correctly, IC transfer can become a significant competitive advantage and revenue generator for forward-thinking repair operations.

Conclusion

IC transfer has revolutionized iPhone screen replacement1, preserving critical functionality while enabling cost-effective repairs. With proper tools, training and high-quality replacement screens2, repair shops can deliver a genuine-like experience that keeps customers returning and helps businesses thrive in an increasingly restricted repair ecosystem.